Hi-Torque Half Stepping!

A better way to get 400 steps/rev...

Roman Black - Aug 2002

This concept is Hippyware

Here is a little-known method for half-stepping,

that has great advantages over conventional half-stepping

techniques:

* more torque than any normal half-step system

* equal torque on every half-step

* equal total current on every half-step

* excellent anti-resonance properties

--------------------------------------------------------

First the 2 "normal" ways to do half-stepping.

Understanding that full steps require 4 steps to a complete

"cycle" giving 200 steps/rev, and that all forms of half-stepping

must have 8 steps to the same complete cycle (400 steps/rev).

Here are the stepping systems shown as currents through the

2 motor phases A and B. The current can be from 0% to 100%.

These current % tables are valid for both unipolar and bipolar

motors alike.

--------------------------------------------------------

First is an example of full stepping, using the current %

table:

Full step (2-phase on):

Step A B

1 +100 +100

2 -100 +100

3 -100 -100

4 +100 -100

--------------------------------------------------------

Now the simplest form of half-step is "crude" half step as

done in many hobby stepper apps using the most primitive

circuits. Crude half-step is the only option when you don't

have fractional currents and the circuit can only perform

on/off coil switching:

Half-step CRUDE

Step A B

1 * +100 +100

2 0 +100

3 * -100 +100

4 -100 0

5 * -100 -100

6 0 -100

7 * +100 -100

8 +100 0

This crude half-step system has many problems. The steps

marked with the * are the same as the fullsteps in the table

above, and have TWO coils on. The other half steps only have

ONE coil on, and the resulting problems are low torque in

some steps and excessive current consumption in other steps.

Unfortunately in the real world the pull-out (rotating) torque

is only as good as the weakest link which is the lowest torque

step.

Half-step CRUDE score:

worst torque = 1

average current = (1+2)/2 = 1.5

max current = 2 (if it stops on those steps!)

torque compensated = NO

--------------------------------------------------------

The second form of half-step system is the Torque-compensated

half step and requires a driver that can have 2 different

current levels for the whole motor (and the ability to turn

phases on/off of course).

This can be done with ONE current adjustment for the whole

motor.

With TC half-step the goal is to keep the torque for all

steps equal. As the 100%,0% steps are already running a coil

at full current the only way to equalise torque is to REDUCE

the current for the steps where 2 phases are on.

ie; you can't improve the weak steps, so you make the strong

steps weak too.

The math model for TC half-step shows that phase currents

of 70.7% in each coil, through both coils, will give the same

torque as the weaker one phase on steps.

With real world motors the fiqures are quite different, and

are around 60% with the motors I've tested. This is due to

the poles of the motor being designed for max holding torque

in the both phase on positions.

Half-step TORQUE COMPENSATED

Step A B

1 * +60 +60

2 0 +100

3 * -60 +60

4 -100 0

5 * -60 -60

6 0 -100

7 * +60 -60

8 +100 0

Half-step TORQUE COMPENSATED score:

worst torque = 1

average current = (1+1.2)/2 = 1.1

max current = 1.2 (if it stops on those steps)

torque compensated = YES

Although TC half-step has advantages of lower total current

consumption and equal torque steps, the one great limitation

of TC half-step is that the torque is still limited to the

max of 1, ie the same torque as a "weak" (one phase on) step.

So ALL steps are weak. But having the same torque on each

step has advantages, as does the reduced and more regular

current consumption.

--------------------------------------------------------

The 3rd (and little known) way of half-stepping:

Half-step CRUDE score:

worst torque = 1

average current = (1+2)/2 = 1.5

max current = 2 (if it stops on those steps!)

torque compensated = NO

--------------------------------------------------------

The second form of half-step system is the Torque-compensated

half step and requires a driver that can have 2 different

current levels for the whole motor (and the ability to turn

phases on/off of course).

This can be done with ONE current adjustment for the whole

motor.

With TC half-step the goal is to keep the torque for all

steps equal. As the 100%,0% steps are already running a coil

at full current the only way to equalise torque is to REDUCE

the current for the steps where 2 phases are on.

ie; you can't improve the weak steps, so you make the strong

steps weak too.

The math model for TC half-step shows that phase currents

of 70.7% in each coil, through both coils, will give the same

torque as the weaker one phase on steps.

With real world motors the fiqures are quite different, and

are around 60% with the motors I've tested. This is due to

the poles of the motor being designed for max holding torque

in the both phase on positions.

Half-step TORQUE COMPENSATED

Step A B

1 * +60 +60

2 0 +100

3 * -60 +60

4 -100 0

5 * -60 -60

6 0 -100

7 * +60 -60

8 +100 0

Half-step TORQUE COMPENSATED score:

worst torque = 1

average current = (1+1.2)/2 = 1.1

max current = 1.2 (if it stops on those steps)

torque compensated = YES

Although TC half-step has advantages of lower total current

consumption and equal torque steps, the one great limitation

of TC half-step is that the torque is still limited to the

max of 1, ie the same torque as a "weak" (one phase on) step.

So ALL steps are weak. But having the same torque on each

step has advantages, as does the reduced and more regular

current consumption.

--------------------------------------------------------

The 3rd (and little known) way of half-stepping:

Hi-Torque Half Stepping!

This is a system that I discovered recently, although I doubt

I was the first to do so. This is a standard principle in

quarter-stepping, but I have seen no mention of it as a complete

half-stepping system. Maybe this web page will help to popularise

a "new" half-stepping system that has a lot of benefits. :o)

To do high torque half-step you need a driver that is capable of

2 different current levels, one for each phase. Then you run one

at 100% current, and the other at 40% current. They coils are

never off, they are either 100% or 40%.

The HT half-step system relies on the fact that there is another

logical way to do half-step, ie when the half-steps chosen are

exactly BETWEEN the standard half step positions.

Half-step HIGH TORQUE

Step A B

1 +100 +40

2 +40 +100

3 -40 +100

4 -100 +40

5 -100 -40

6 -40 -100

7 +40 -100

8 +100 -40

So there are still 8 steps to a cycle, and 400 steps/rev, like

all other forms of half-step.

But it now runs at the MAXIMUM current and torque of any possible

half-step system.

No coil is ever off, and the current (and magnetic field) are

equal for every step, so it doesn't need to be tuned to give

equal torque on each step, although it may need tuning for step

angular position.

Also, since stepper motor pole construction is optimised for

max torque at positions where both phases are on, there is a

significant torque advantage to always having some phase current

and bringing the rotor closer to the (stronger) pole position.

In my case the motor tested at 28% more torque which is very nice

to have when building a machine. :o)

Half-step HIGH TORQUE score:

worst torque = 1.28 (every step)

average current = 1.4 (every step)

max current = 1.4 (every step)

torque compensated = YES

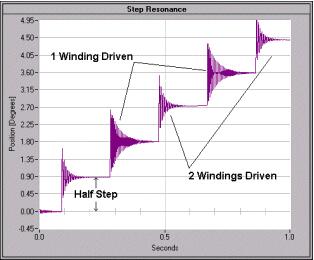

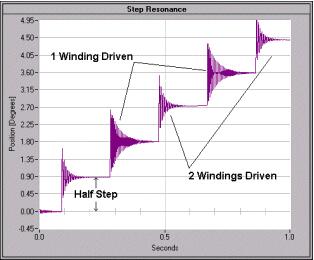

Another nice benefit I found is that resonance is greatly reduced,

and the motor performs more like a microstepped motor. This is

because these new angular step positions are less "in phase" with

the full step pole positions where the maximum resonance occurs.

Of course having 28% more torque and no torque ripple helps a lot

and the motor performs well both at high and low speeds.

-end

--------------------------------------------------------

Interested:

Questions:

-

@spam@ajay_281083 at yahoo.com

asks:

actualy how we get half step. I want the procedure of half step. which type

of program you write to step down form 1.8degree to 1.4degree ie full step

to half step.

James

Newton replies: Just turn TWO coils on at the same time between the

steps where you turn only one coil on. This creates a new set of positions

half way between the standard, full step, positions and doubles the total

positions in the system.+

+

-

@spam@amroe at tpg.com.au

asks:

Great, useful site (and probably useful kits and concepts too). Perhaps it's

my failing memory, but my recollection is that all the old disc drive stepper

drives used "one coil on" for full steps, and "both coils on" for the half-steps

when needed (rather than the other way 'round). The fact that 60%+60% typically

yields similar torque to 100%+0% indicates that the "one coil on" positions

are more efficient for motor geometry (ie, torque vs total current), although

the "both coils on" positions" still win in overall efficiency because of

the reduction in copper losses. I've looked into the +/-100%, +/-40% drive

method, and it does seem to offer the smoothest possible operation, although

I can't yet see how it would yield a 28% torque improvement for the same

power input. That said, there is no down side, so I'm prepared to try it

out, and once I digest the rest of the website I expect to contact you again

for a parts order.

+

Comments:

-

Robert Mazziotti

I found some half-step code for arduino, and made the appropriate minor changes to implement this hi-torque method, and it is really excellent. it gave me a much more reliable sweep, 25% faster than the full-step code I started with. the code changes I had to make are: #define LOWX 0, MEDX 511, HIGHX 1023, alter the 8 steps to use these values, per the pattern above, use pins 5,6,10 & 11, replace digitalWrite() with analogWrite(). so easy, and so helpful. thanks!!!

+

-

This "Hi-Torque Half Stepping" idea is really brilliant.

I find that I can apply this procedure to my existing resonating, buzzing

and skipping design whit very litle effort.

As I'm using scavenged STK6713BMK4 "hybrid" chips from Sanyo, all I need

is a few extra resistors and transistors, and 2 aditional I/O lines from

my microcontroller.

For those few who might happen to have a few of these floating about, I might

provide my design, if you like.

James

Newton replies: Please do+

+

| file: /Techref/io/stepper/linistep/halfstep.htm, 11KB, , updated: 2019/5/9 16:20, local time: 2025/4/25 08:34,

owner: RB-ezy-Q33,

|

| | ©2025 These pages are served without commercial sponsorship. (No popup ads, etc...).Bandwidth abuse increases hosting cost forcing sponsorship or shutdown. This server aggressively defends against automated copying for any reason including offline viewing, duplication, etc... Please respect this requirement and DO NOT RIP THIS SITE. Questions?

<A HREF="http://linistepper.com/techref/io/stepper/linistep/halfstep.htm"> Hi-torque half step, half stepping, half-step, quarter-step, unconventional half step, LiniStepper, lini, stepper, linear, 6th microstep, linear microstepping stepper motor driver, </A> |

| Did you find what you needed?

|

Half-step CRUDE score:

worst torque = 1

average current = (1+2)/2 = 1.5

max current = 2 (if it stops on those steps!)

torque compensated = NO

--------------------------------------------------------

The second form of half-step system is the Torque-compensated

half step and requires a driver that can have 2 different

current levels for the whole motor (and the ability to turn

phases on/off of course).

This can be done with ONE current adjustment for the whole

motor.

With TC half-step the goal is to keep the torque for all

steps equal. As the 100%,0% steps are already running a coil

at full current the only way to equalise torque is to REDUCE

the current for the steps where 2 phases are on.

ie; you can't improve the weak steps, so you make the strong

steps weak too.

The math model for TC half-step shows that phase currents

of 70.7% in each coil, through both coils, will give the same

torque as the weaker one phase on steps.

With real world motors the fiqures are quite different, and

are around 60% with the motors I've tested. This is due to

the poles of the motor being designed for max holding torque

in the both phase on positions.

Half-step TORQUE COMPENSATED

Step A B

1 * +60 +60

2 0 +100

3 * -60 +60

4 -100 0

5 * -60 -60

6 0 -100

7 * +60 -60

8 +100 0

Half-step TORQUE COMPENSATED score:

worst torque = 1

average current = (1+1.2)/2 = 1.1

max current = 1.2 (if it stops on those steps)

torque compensated = YES

Although TC half-step has advantages of lower total current

consumption and equal torque steps, the one great limitation

of TC half-step is that the torque is still limited to the

max of 1, ie the same torque as a "weak" (one phase on) step.

So ALL steps are weak. But having the same torque on each

step has advantages, as does the reduced and more regular

current consumption.

--------------------------------------------------------

The 3rd (and little known) way of half-stepping:

Half-step CRUDE score:

worst torque = 1

average current = (1+2)/2 = 1.5

max current = 2 (if it stops on those steps!)

torque compensated = NO

--------------------------------------------------------

The second form of half-step system is the Torque-compensated

half step and requires a driver that can have 2 different

current levels for the whole motor (and the ability to turn

phases on/off of course).

This can be done with ONE current adjustment for the whole

motor.

With TC half-step the goal is to keep the torque for all

steps equal. As the 100%,0% steps are already running a coil

at full current the only way to equalise torque is to REDUCE

the current for the steps where 2 phases are on.

ie; you can't improve the weak steps, so you make the strong

steps weak too.

The math model for TC half-step shows that phase currents

of 70.7% in each coil, through both coils, will give the same

torque as the weaker one phase on steps.

With real world motors the fiqures are quite different, and

are around 60% with the motors I've tested. This is due to

the poles of the motor being designed for max holding torque

in the both phase on positions.

Half-step TORQUE COMPENSATED

Step A B

1 * +60 +60

2 0 +100

3 * -60 +60

4 -100 0

5 * -60 -60

6 0 -100

7 * +60 -60

8 +100 0

Half-step TORQUE COMPENSATED score:

worst torque = 1

average current = (1+1.2)/2 = 1.1

max current = 1.2 (if it stops on those steps)

torque compensated = YES

Although TC half-step has advantages of lower total current

consumption and equal torque steps, the one great limitation

of TC half-step is that the torque is still limited to the

max of 1, ie the same torque as a "weak" (one phase on) step.

So ALL steps are weak. But having the same torque on each

step has advantages, as does the reduced and more regular

current consumption.

--------------------------------------------------------

The 3rd (and little known) way of half-stepping: