SECTION 1 Hardware Tools

Chapter 1

Introduction

The three displays of the Simple Bike Computer are shown below in fig0 They

switch automatically in the sequence .. Speed… Distance

…AverageSpeed… Speed etc

There are so many embedded controller products in the house these days that

many of us feel we ought to know a little more about how they work. They're

the brains inside things like the washing machine and so many other present

day domestic appliances.

My first personal microchip contact was a friend's radio controlled car which

“died” and was brought to me for repair I being his resident radio

expert.

The opened toy had very little inside, a small receiver, ( it was ok) and

a small chip beside it, controlling the motors to the wheels. The chip was

a PIC. I was out of my depth, best learn how….!!!

The reason for the PIC being there was obvious to me as an engineer. The

printed circuit board was surprisingly empty. That meant the PIC program

was replacing a lot of the traditional circuit's resistors diodes and other

hardware.

I decided I wanted to do something similar . Learn how to program was a priority

in my mind, but not as a theoretical exercise, no, I like to get something

useful at the end of any project.

Bathroom Scales? No, nor a toaster, nor the water heater. They all involved

a lot of hardware, with unfamiliar thermistor sensors. My thoughts turned

to my bike. It had a computer, very small and the sensor input was minimal.

Yes, that was it, a Bike Computer project….. and so it

started.

Our Goal

The bulk of the article that follows is to try and take the mystique

out of the many steps involved in going from an idea to a finished product.

You won't of course be ready to go into full scale industrial production,

but you will now be aware of the things that have to be done, and know how

to do them.

We will look at and master.

Hardware steps

-

Making a PCB from scratch

-

How to use the FREE tools

Software steps

-

-

Very basic Pic source coding

-

Using MPASM

-

Getting the HEX into the PIC

And that is about it. There is NOTHING in the above list that is difficult.

Most of the steps only require time and patience.

WARNING. We

will use no poisonous chemicals , BUT they can BURN HOLES in

you or your clothes.

So when you are making the pcb, PLEASE keep the CHEMICALS away from

the reach of children who are always curious about something

new.

The Master plan

There are many ways to plan a project. But often, the steps we know don't

even figure because they are so obvious….This can cause enormous headaches

for us beginners. So we will try and follow a logical sequence by spelling

out everything that has to be done . There are two big areas to cover, the

hardware and it's construction, then the software and it's application. The

hardware is generally said to be the easiest part of the two so lets start

there.

Note. The current saving techniques such as sleeping the PIC until a wheel

interrupt is detected had to be abandoned when we ran out of memory space.

Even so with the battery 4xAA, this is not a problem for the tests.

Getting the Act together

The initial project outline was supposed to show the major activities and

thus the equipment needed. The “equipment” including physical things

like PCB and program things like the micro and language. The “idea”

diagram is very bare and cryptic, but gets filled in as the project progresses.

So we start with.

fig1 .Start

It was very clear from the start that ( for me ) the hardware box was easy

to define and make, whereas the software box was full of unknowns. So let's

look at the Software questions.

What is a microcontroller ? and Which microcontroller?

I had found out by then that microcontroller is not just another word for

microprocessor, no indeed. A micro controller is a stand-alone system that

can calculate and connect itself with minimum peripherals directly to the

outside world. The microprocessor also can calculate but needs a lot of

interfacing to get the results to a screen or to a display.

Which microcontroller was harder to get to grips with. After going through

an initial list it became all too clear that the abundant choice was aimed

at experts, it was not for a beginner. That narrowed things down. The PIC

, my first contact, caught my eye time and again, because of the many articles

on offer on the internet and more important, explaining how to make things

with it.

So I read more; specifically about PICs to find the really basic stuff. The

PICLIST was a great starting point, as it talked about activities I had never

even thought about. Especially, how do you test what you are proposing to

make, some sort of simulation was an obvious must. This narrowed the field

down further to things like the 16C84, now slightly obsolete.

Which PIC language?

My searching had uncovered a company called Microchip, which had from the

goodness of it's heart provided a program to check that the code you were

writing was correct. It had a site that offered data sheets on it's products,

and almost all the net sites that talked about PIC's directed you there.

What nobody actually said was which language was better,

ASSEMBLER OR C ( OR C++, OR ???).

As I know a little about C it initially attracted me, but somehow I began

to get the feeling it was an overkill and that the routines were a bit unwieldy.

Also it seemed to be an additional buffer between you and the microcontroller.

During my search someone had commented in an article that correctly written

assembler was very compact and made best use of the “scarce” memory.

So I decided on Assembler. But what was exactly assembler? I thought assembler

code was universal, but it comes in many flavours. PIC assembler is not the

same as that of Intel nor Motorola to cite some of the more important names.,

but PIC was widely used. Not a very logical way to arrive at a conclusion,

but it happened that way.

The Software Shopping List

We now had a starting point and the needed bits and pieces began to become

clear.

-

Find a tutor which explained the PIC

-

Find out how to use MPASM

-

Find out about MPLAB

-

Find out how to get the code into the PIC

The Tutor

There are so many. However one caught my eye as it was big, illustrated and

FREE. After working through it steadily for a couple of days, it pointed

me towards two important areas for getting started.

·To generate the code, you need something to write

it with

·To run the code, you need some program that does

exactly that

After a week of reading the tutor I found I could not put off any longer

doing something about getting a suitable editor and an emulator. They had

to be obtained.

Text Editor

When I'm not writing with a word processor, I use a smaller freeware program

called EditPad . The big word processing programs use a lot of control characters

which the PIC doesn't want, (nor does it know what to do with them).

EditPad light is FREE, and also adds nothing to give the PIC indigestion.

However any small Text Editor designed specifically for writing programs

should be fine.

MicroChip's MPLAB

This is a big big program…. Why chose it ? Well ….

-

It is the recommended PIC maker's program.

-

It has lot's of bolt-on goodies for when we are more advanced or

well-heeled.

-

It can interface, input and output, with other programs,

-

It accepts C as well as assembler or a mix of both

-

It is not too hard to use though telling it what you want to do has to be

exact.

-

It can handle the basic 16C84 as well as it's bigger brothers

-

It is FREE.

The program to get our program into the PIC

The MPLAB after checking that the code written can run error free finally

produces a compiled file with the extension xxxx.HEX.

This .hex file is what the real world PIC needs to get up and running.

But to get the HEX file into the PIC we need a program that can check the

PIC , we need a program that can read the contents of the PIC and write the

code INTO it, burn it.

I personally like a nice little program that does this called ICPROG. The

name I think says it all. It is a program to program your IC, your integrated

circuit, your PIC!!!

It also caters for many different PICs.

ICPROG is easy to use and is , yes you guessed, it is FREE.

Starter Kit

So where can we find all these programs? On the internet of course! If you

search with the names above you will find several sites, some of which will

be the nearest to your location.

If you don't find any of them, then try the list at the end of the chapter

which is hopefully not out of date. These sites will let you download the

needed programs. Try it at night, because some programs are VERY BIG. I'm

referring specifically to MPLAB.

We still have one very important item to add to our shopping list…..the

data sheet for the PIC.

Which one?

Well the 16F84A is a bit bigger memory wise than the original 16C84

and is still not classed as “obsolete. It is limited as far as built

in goodies are concerned.

E.g. you don't get on-board voltage references, nor UARTS nor ADCs, it is

a little slower, but this is good for us learners because it is simpler to

learn with. The bigger chips tend to have so many trees that it gets hard

to see the forest.

To sum up , we need :-

| Item |

Source |

What it does |

| 16F84A data sheet |

Microchip Site and others |

Explains about the PIC |

| Text Editor |

EditPad Site |

For writing no-frills Text |

| MPLAB |

Microchip Site and others |

Test drive your code |

| PIC tutor |

Mikroelektronika |

Tells you How the PIC works |

| ICPROG |

Icprog site |

Stuffs the PIC |

| LCD data sheet 2x16 |

Hitachi 44780 controller |

displays speed, time dist. |

Up to here the total cost is your telephone InterNet

connection

Bill

Once we have these items we can start to get to grips with the bicycle itself.

So let's see what the computer needs to get up and running. We will talk

about the program later.

Defining the Computer

Here I can use a bit of hind-sight and point out things that are to be avoided.

All bike computers have at least one input from a sensor, most will have

this sensor plus a couple of buttons for changing menus. But the essential

part is the sensor which sends a pulse to the PIC.

Sensors

The sensor could be mechanical and every time the bike wheel turns it closes

a switch, or it could be optical and every time the wheel goes round a photocell

detects ( or loses) a light beam.

The mechanical contact on a mud covered mountain bike would be pretty unreliable,

not only because of mud blocking the contacts but the bumps and leaps would

give false readings.

The optical systems are very reliable in general, but not in the mountain

bike situation. A piece of mud covering the detectors eye would happen so

frequently that it would make the detecting system useless.

What's left? Many systems. Just to give an idea of what is possible at the

exotic end, you can carry a GPS terminal. Gives you all the travel data you

want including the names of the place and country you are in, but a bit pricey.

Besides we want to make it ourselves and write the program all at a very

low cost. So is there a low cost reliable sensor?

Well the magnet on the wheel type is almost universal. It is cheap, very

reliable and vibration proof for 20 years or so. ( Theoretically, the bike's

vibration, the flexing of the spokes, all will cause it eventually to demagnetise

itself).

Another thing is that I don't know anyone who has a 5yr old bike computer

as we all tend to buy something more up market or simply get bored with our

present one and buy another.

Getting back to the wheel magnet. It is fixed to a spoke, and usually on

one side of the fork there is a detector. The magnet is aligned to pass this

detector at a distance of not more than 1 to 3 mm every time the wheel rotates.

(Less might be too close as the spoke flexes when the mountain bike lands,

and magnet and detector could become entwined in each other with bad karma

for the bike rider.

The magnetic detector can have many forms. It can be a many turn encapsulated

coil, it can be a HALL EFFECT device proper, or it can be an MR (

magnetoresistive) device, or a Weigand sensor.

But let's stick with the crowd and use a Hall effect sensor. It has a few

drawbacks, but we can always change it later if we want to experiment.

So we want a detector which changes it's output( goes high) every time the

magnetic field gets close, and reverts to its low state when the magnet goes

away. This is usually called a UNIPOLAR Hall effect device.

We want one with all the trimmings, (we don't want to get involved in additional

hardware design). That is , we want a sensor output with the correct level

and good signal conditioning which gives clean, bounce free, and cmos level,

HIGH and LOW states. There are quite a few to choose from. Melexis, Micronas,

Allegro, Siemens… etc etc. So now for our first drawing of the computer

below, + fig.2

fig. 2

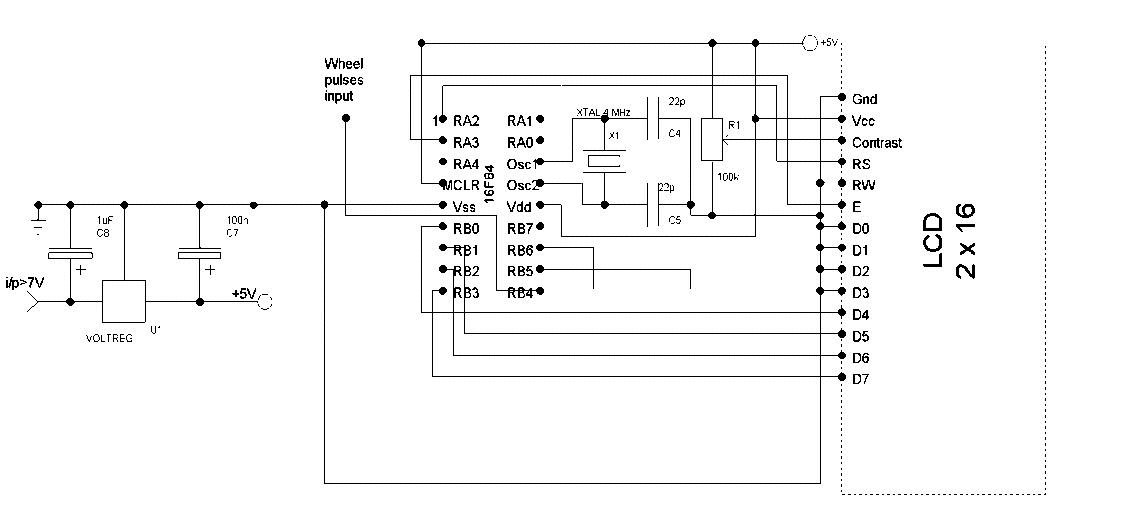

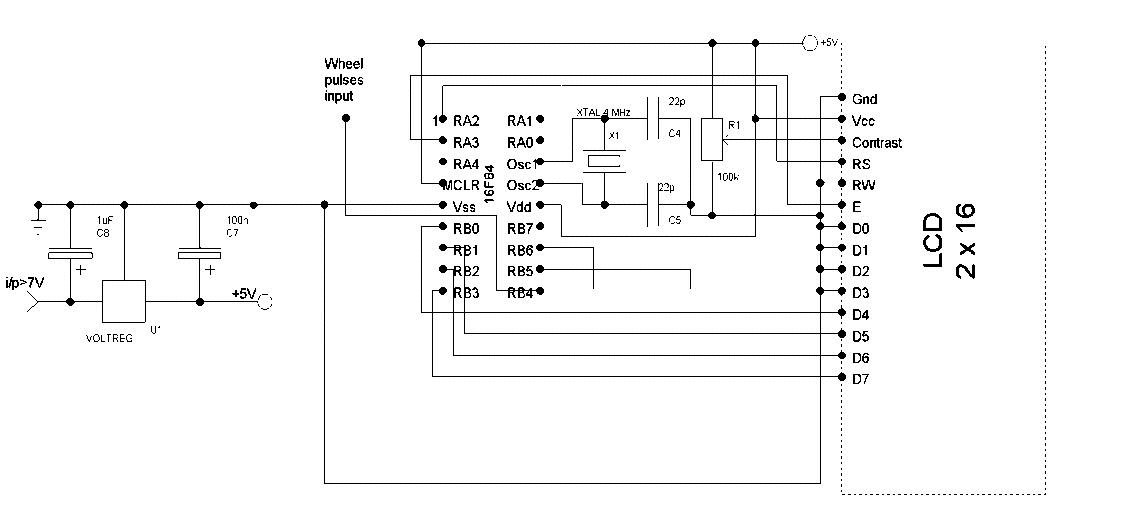

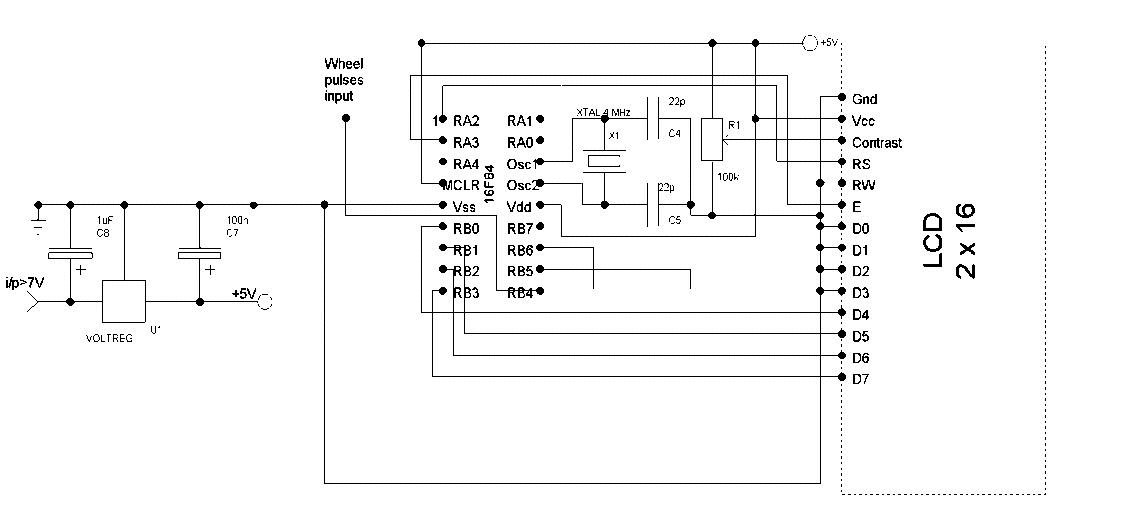

Well fig.2 needs to be padded out a bit with things like what pin goes where,

the connections between pins, and the power supply. To make things easier

for those of us who have never seen a PIC before, lets just look at a

bit of the complete theoretical drawing

to comment the components and functional blocks involved.

Note if 2 wires cross with no dot, they don't touch, if they have a dot where

they cross , then they do touch, i.e., they make contact with each other.

fig.3

On the LEFT we have an integrated circuit ( between the two capacitors) which

needs a minimum i/p of +7V to guarantee a stabilized output voltage of +5V,

On the bike of course this would be a battery.

The next important point is the wire with the legend “Wheel pulse i/p.

On the bike, this is where the sensor sends its output pulses to. Here testing,

we have no bike, instead we generate pulses with another circuit ( a555).

We will talk about the 555 later, it is nothing special, but clutters our

initial view of the Bike computer.

The original project started with a PIC 16F84, but began to run out of memory.

Fortunately it has a big brother, the 16F84A , with the same pin connections

and accepts nearly the same code.

Just to the right of the PIC is the 4MHz xtal oscillator, composed of a 4MHz

xtal and two 22pF capacitors. At such a low frequency the crystal is not

very fussy, providing it is sited near the chip and we have short connections

to the earth plane of the PCB.

Just beside the Xtal block, there is a 100k potentiometer. It adjusts the

contrast of the LCD display. This pot is also non-critical, once adjusted,

you will probably forget about it. So why have a pot there?

The problem is the display contrast. If your display gets fried and needs

to be changed, then it is almost a certainty that you will have to readjust

the pot to get the display contrast back to the “optimum viewing

position”.

In fact my original display would only become visible with a NEGATIVE voltage

applied. Still lets hope there aren't many of those left on the components

suppliers shelves.

The last block is the display itself. There is an LCD standard, a 2 line

by 16 character unit, which is show on top of the introduction on page 1.

The display is the Hitachi type,

( there are many clones), but the important thing is that it has a 44780

controller on board. This is essential as all that follows presupposes that

we are dealing with a 44780 controller to get our information to the

display.

The PIC's 18 pins

Lets look at the previous diagram again, focusing on the various pins of

the PIC.

fig3b

Vss goes to ground and Vdd as well as the reset MCLR to the positive +5V

rail. The osc1 and Osc2 pins were mentioned previously from the point of

view of their physical position. The oscillator itself needs two external

capacitors to function correctly. We have chosen a capacitor value of 22pF

, which should be valid for most xtals. ( Here valid means that the xtal

will see a suitable load and will oscillate correctly). The RA pins and the

RB pins can be used as either input or outputs. The trick is to make the

unused port pins OUTPUTS. Why not inputs? Well this is cmos and you would

be wise to tie them to a reference, probably best, to ground. But then if

you want to use the unused inputs later , this would mean track cutting.

However an unused output can be left free. A reprogram can change it into

an input, with no knife work involved. We mentioned above that there are

RA pins, five of them, for PORTA. Only 2 RA pins are used to connect to the

RS and E pins on the LCD , the other three are programmed as outputs and

are not used. The two RA pins used (PORTA), essentially handshake the data

transfer and indicate we are doing this in the half-byte or nibble mode of

operation of the LCD.

The actual data is sent from PORTB to the LCD. It has to enter the LCD on

pins D7-D4 for the half byte mode of operation. The remaining LCD data input

lines are not used and to be safe, they are tied to earth as we talked about

before. So D0-D3 are connected to ground directly. The data transfer from

the PIC has a restriction, the high nibble always has to be sent first to

the LCD, then the low nibble.

Is that about it? Well almost. The PORTB has 8 pins and any of them could

be programmed as outputs or inputs. But there is another consideration. Later

we will need to use some of these PORTB pins as inputs. Now only pins B4-B7

will give an interrupt signal asking for service. This means that the data

out to the LCD can only be on pins B0-B3.

As an example, the wheel pulse INPUT SIGNAL ( having chosen PORTB), has got

to go to one of the B4-B7 group as an input. It is seen to go to pin B4.

Later we will use the other pins for buttons and LEDS during debugging .

This is an initial hardware justification, not complete but enough for the

moment to enable us to get to the next stage which is mounting the PIC on

a board to be able to program it.

Where to find the Starter Kit